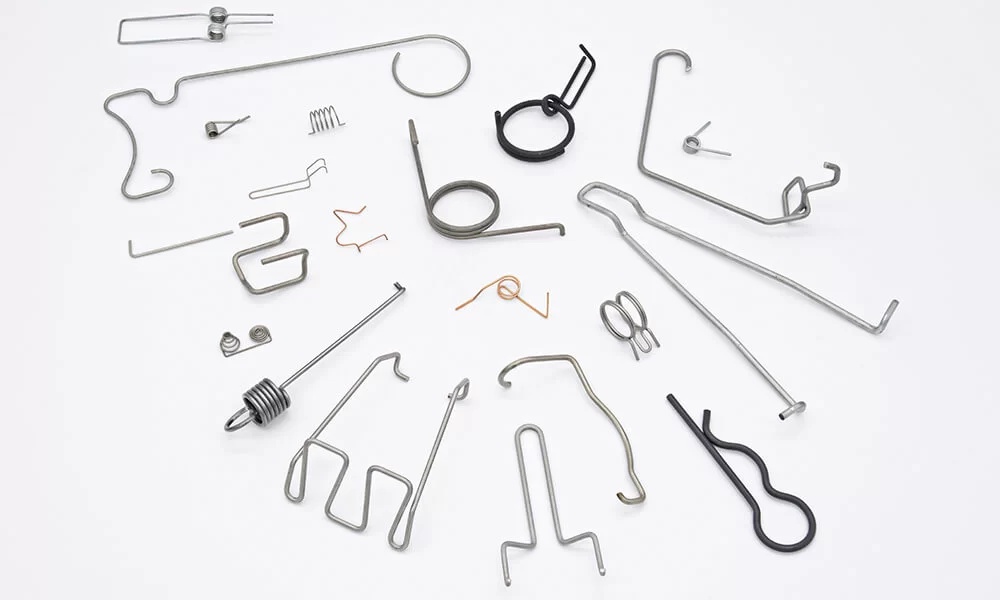

Customized Wire Forming

Work with a variety of materials, with the most common being steel, stainless steel, aluminum, and brass. Any finishing processes such as heat treating, plating, and painting, can be arranged.

Using the latest wire forming technologies, we manufacture all types of custom wire coils and wire-forming components. From custom D-Rings and S-Hooks to unique wire-bending shapes. Our wire forming expertise offers component prototypes, fabrication, finishing, assembly, and packaging. Plus rock-solid quality service and design engineering experience from our dedicated spring engineering and manufacturing team.

The Versatility of Wire Forming

Form wire in one operation

Large or small runs

Great for prototypes

Short lead times

Modifications and unique designs can be produced

Small to large size wire diameters available

Wire types – Titanium, stainless steel, steel alloys, nickel alloys, high-carbon steel and copper alloys

Benefits of Wire Forming

Why use custom wire forming? With wire forming very little or no additional tooling is required. Therefore, added costs are typically minimal. Wire forming is a quicker process than hand or air-bending. And no maximum length limitations on the length of wire used in each part. After customers have experienced the design engineering and order process to develop and manufacture a custom wire form design, the reorder process is easy, quick and very cost-effective.

Categories

Contact Us

- +86 532 8262 0751

- +86 15964209667

- sales@haxinehome.com

- +86 15964209667